PC-1N Series Power Amplifiers Tidak Dilanjutkan

Learn More About EEEngine

EEEngine delivers incredible power while preserving sound quality

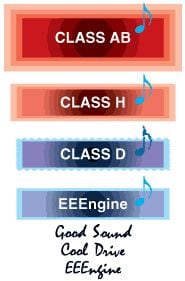

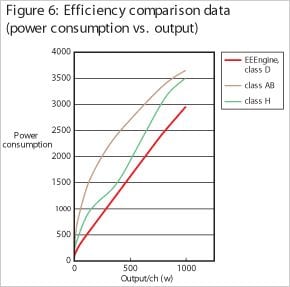

As a power amplifier's output increases, its driving mechanism becomes more significant. Yamaha's exclusive EEEngine amplifier driving technology supplies the voltage level necessary for the level of input signal through switching circuit and smoothing circuit, producing a highly effective driving mechanism. This is a revolutionary power amplifier driving technology that offers the function of a Class AB amplifier and the efficiency of a Class D amplifier. EEEngine gives you fantastic power, highly efficient driving function, and tremendous energy savings, all without sacrificing the sound quality demanded of a professional power amplifier. This technology is included in many of Yamaha's power amplifiers, and proves its utility in all kinds of situations, from sound reinforcement to permanent installation.

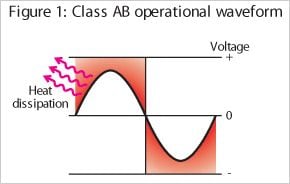

Conventional Amplifier - Class AB

Until now, the Class AB system has been the norm for power amplifiers. This system offers a simple circuit configuration and superb sound quality. However, its drawback is that its output stage always requires driving at the voltage for maximum output, resulting in a great deal of heat dissipation. Various methods have been developed to overcome this drawback in Class AB systems. Class H and Class D are typical of these developments, but they have their problems as well.

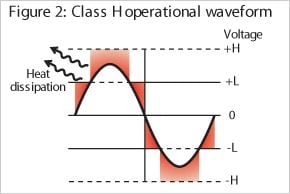

Voltage Switching - Class H

Class H uses a method that switches the voltage level according to the input signal. This can vastly improve output stage heat dissipation when driving with a small signal at low power source. However, as the signal level increases, the system functions in the same way as a Class AB system, and efficiency is lost. Class H is not intended for music signals with wide dynamic ranges. A system that uses a multi-step voltage switching method could be considered to improve efficiency for music signals, but this would increase switch loss and the number of elements, making it impractical as a solution.

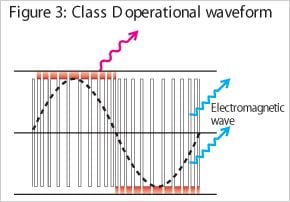

PWM: Pulse Width Modulation - Class D

Individual parts that are to be used in Yamaha products are thoroughly tested to ensure that they meet performance specifications, and that they will maintain their performance through extended, repeated use. Mechanical parts such as controls and faders are subject to particularly stringent tests. Control samples must undergo tens of thousands of operating cycles without failure before they are approved for use in Yamaha products. Even cables are subject to extensive flexion testing under load. Parts that can be damaged if physically opened are examined using advanced non-destructive x-ray tomography techniques, and many parts and finishes are carefully tested for potentially hazardous VOC (volatile organic compound) emission. There's more, but this abbreviated list should give you an idea of the degree of the detail and depth of the testing that is required for each and every Yamaha product.

State of the Art: Yamaha EEEngine

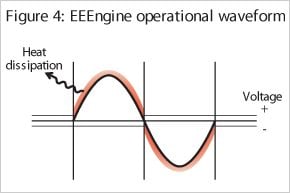

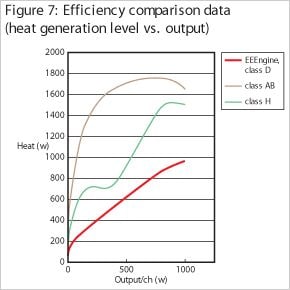

EEEngine overcomes these problem spots while providing advantages in all areas, offering a dramatic leap in power amplifier design. It realizes efficiency that matches Class D without compromising the sound quality of a Class AB amplifier. Furthermore, EEEngine solves all of the problems of weight, size, and heat generation that users of large-output power amplifiers often encounter.

EEEngine tracks the audio signal to always provide the minimum power needed for the final output stage, allowing for surprising improvement in efficiency. It utilizes Class D operation to provide the power at the final output stage of Class AB operation. Almost all of the current energy is outputted as the audio signal, and just a small fraction of the remaining energy is emitted as heat dissipation through the heat sink.

With the final output stage operating at Class AB, the output signal is of remarkably high sound quality. The signal remains analog from input to output, without being converted to a PWM signal. There is none of the deterioration of frequency response and damping factor found with Class D systems. Plus, EEEngine is designed to operate perfectly while keeping the power amplifier heat generation to a minimum, regardless of the load requirements. All together, you get Class AB sound quality with efficiency that matches Class D.

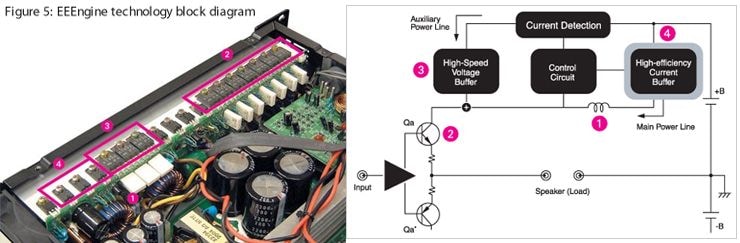

- A main power supply line that supplies driving power to the speaker

- A high-efficiency current buffer combing a switching element that switches the main power supply line on and off with a leveling circuit

- A control circuit that varies the on/off switching frequency according to the input signal level

- An auxiliary power line that supplies power independent of the main power supply in quick response to the input signal level

- A high-speed voltage buffer and current detector that adjust and control the auxiliary power supply level

- This arrangement ensures efficient and highly accurate power amplification even when input signal amplitude rises steeply

Keeps up with sharp increases in sound

EEEngine's auxiliary power supply works with the main power supply to always drive at just the right power current to obtain maximum output, providing a high following capability even when there are steep increases in sound. This reduces power consumption while maintaining the special features of a "Fast amp." Plus, even when driving the fast auxiliary power supply in this method at ample voltage, power provided from the main power supply unit is very efficient at normal times, reducing the average current value and dramatically improving power loss.

Improved parts life and reliability

In addition to its tremendous improvements in efficiency and preservation of great sound quality, EEEngine plays yet another important role. It is often said that a power amplifier's parts will last twice as long if the internal temperature is reduced by 10 degrees Celsius. EEEngine's heat generation during usage is 35% less than previous systems, contributing greatly to improvements in durability and reliability.